TEKON adapter for EOL testing

Functional and process-safe testing technology

Electrical engineering has opened up new areas of application in recent decades. Today, electrical devices that must ensure functional reliability for the user can be found in almost all areas of life. To achieve this, they are meticulously tested during the production process. Testing with commercially available connectors, however, causes great wear and tear and leads to high costs.

The professional TEKON contacting systems, on the other hand, are high-quality, low-wear and generate enormous savings potential thanks to high process reliability. TEKON test fixtures are also characterized by low, repeatable contact resistances and easy handling. In addition to the innovative character, our customers benefit from the durability and reliability of the adapters.

Precise electrical contacts

DUTs can be safely connected electrically by TEKON test fixtures. A test fixture is used for contacting one or more electrical interfaces and connects them to a test device. The contacting is primarily done by means of spring contact probes, levers and/or TEKOFLEX. Data evaluation is carried out by customer-specific test units, which can detect faults or demonstrate compliance with quality criteria.

Focus on customer requirements and economical testing solutions

As specialists, we provide holistic advice – always taking into account aspects of economic efficiency. This is the only way to meet all requirements. Of course, we take into account the test environment directly on site. In the sense of technological openness, we cooperate with a professional partner network.

Process-safe testing solutions in standard and individual design

With this procedure, more than 15,000 adapter solutions for process-safe, sensitive testing of electrical plugs and sockets have been created to date. TEKON test adapters are used wherever series-accompanying functional tests are carried out: from simple standard applications to complex individual solutions.

Even if a project is urgent: From inquiry to delivery to service, we respond quickly to all requests.

TEKON test adapters at a glance

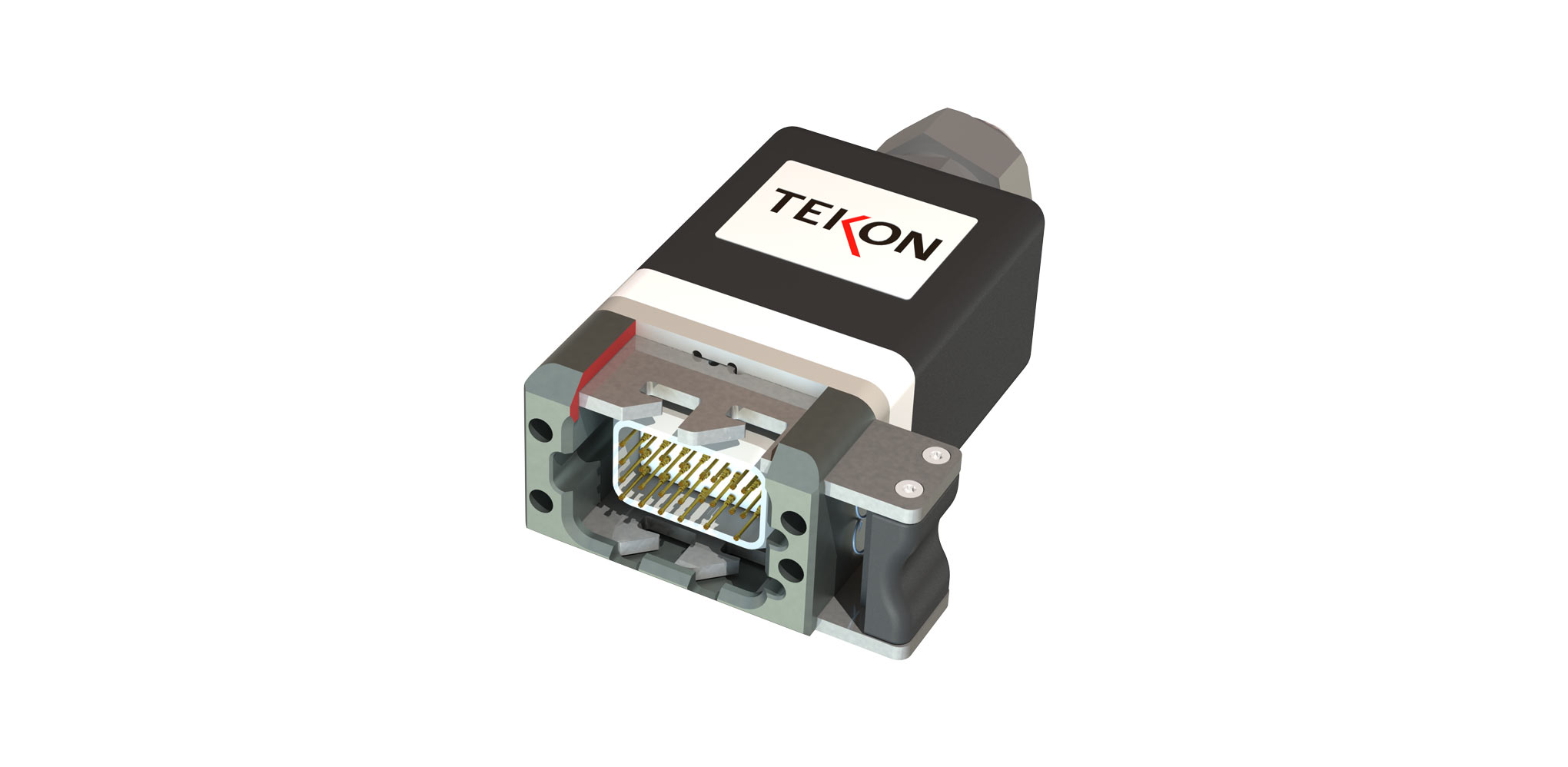

Contact plug with spring contact pins

Contacting to the front surface of the test pins

Conceptual advantages

- Most cost effective arrangement

- Easy exchange of contact elements

- No grinding marks on the test piece pin

Manual operation

Contact plug in ergonomic design for operation by hand. Contains latching element to prevent unintentional loosening of the contact.

Automatic delivery

Contact plug for tolerance compensation with floating bearing.

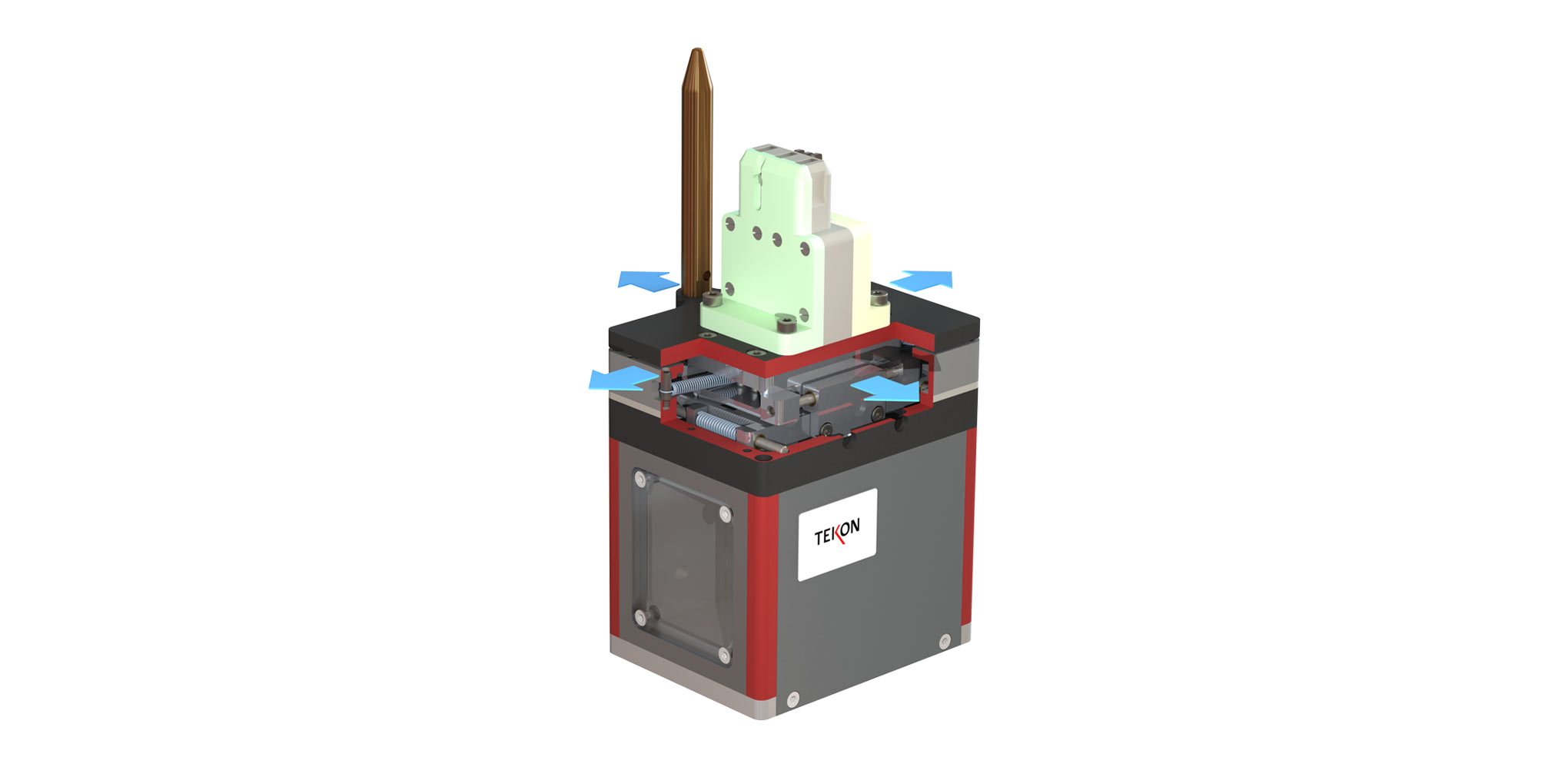

Contact plug with contact levers

Passive contacting: arranged as pincers, slides laterally on the DUT pin during contacting

Conceptual advantages

- No ejection force with mated contacting

- Higher contact forces and thus lower contact resistance

- Four-wire measurement can be easily implemented

Manual operation

Contact plug in ergonomic design for operation by hand. Contains latching element to prevent unintentional loosening of the contact.

Automatic delivery

Contact plug for tolerance compensation with floating bearing.

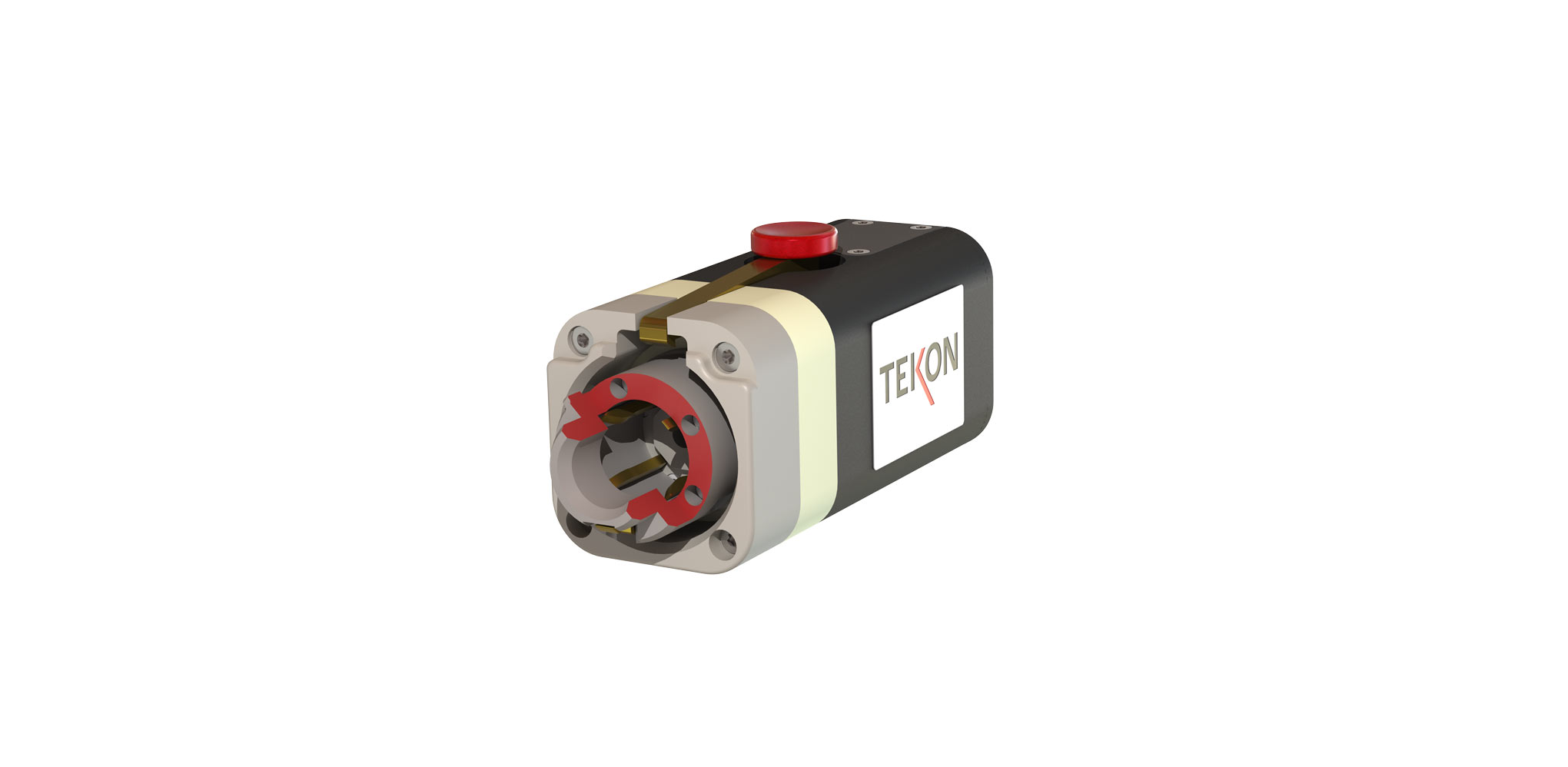

Contact plug with "active" contacting

Active contact tongs are guided over the test specimen without contact and are fed with a drive (pneumatic or electric).

Conceptual advantages

- Even higher contact forces and lower contact resistance

- No grinding marks on the test piece pin

- Force-free insertion and removal of the contact

Automatic delivery

Contact plug for tolerance compensation with floating bearing.

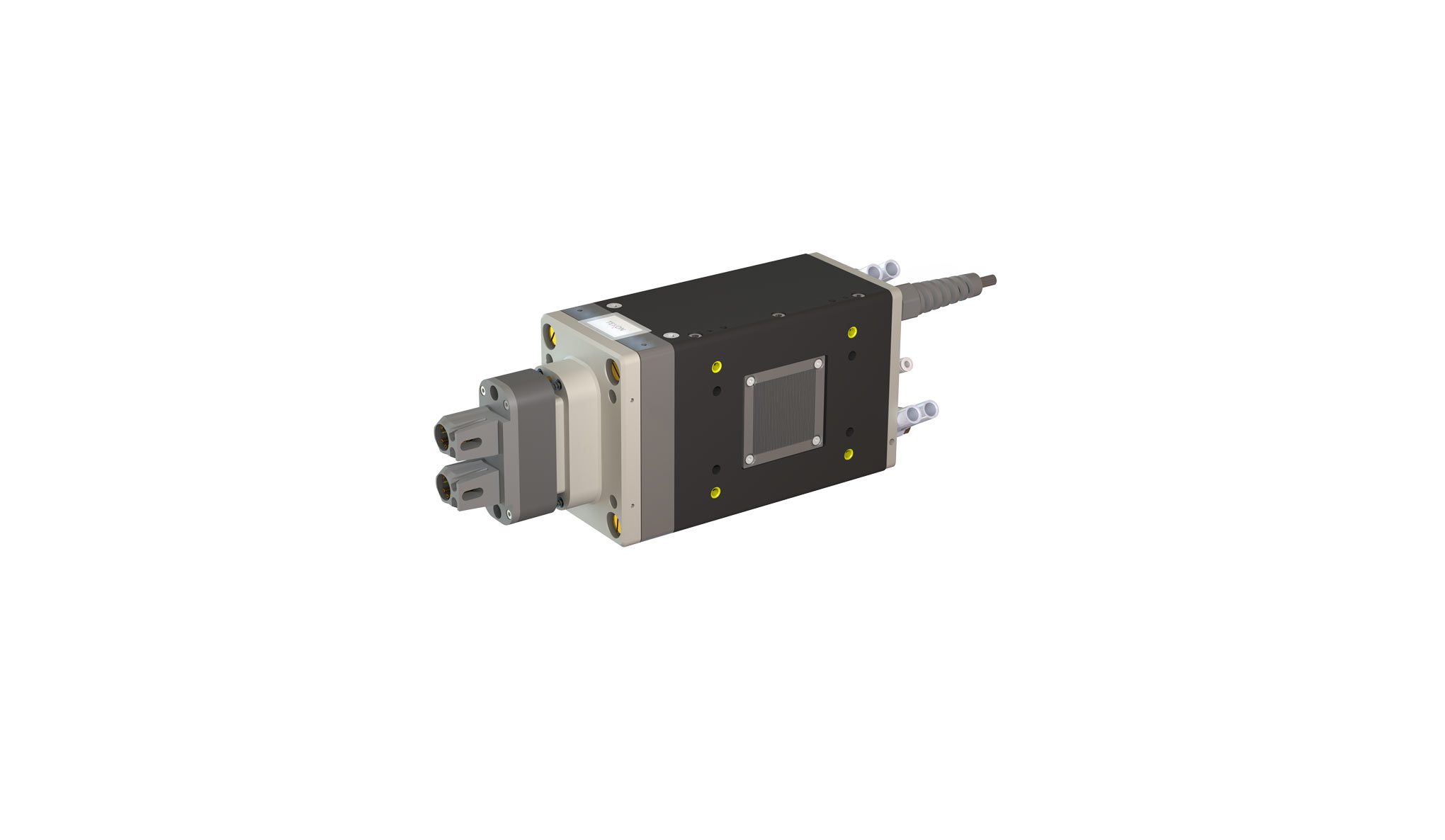

Technological expertise thanks to many years of market experience

TEKON stands for innovative solutions in the field of electrical contacting and a strong sense of quality “Made in Germany”. Not least because of the high commitment and creative inventiveness, many TEKON innovations have developed into industry standards. Based on specific test requirements and existing expertise, we develop test fixtures with repeatable mating behavior that do not influence the quality of the measurement result. By means of one hundred percent final inspection with simulated motion sequences, we verify the product characteristics before delivery.

Based on the TEKON test fixtures, we also produce extensions and interfaces for a wide range of applications, such as Industry 4.0-capable, intelligent test fixtures with TEKONect monitoring function. In addition, combined leak and function tests with sealed adapters, precisely fitting tool carrier interfaces as well as feeding devices.

Almost 40 years of experience in testing technology for the automotive, aerospace, household appliance, construction and agricultural machinery, medical technology and other industries:

- Individual consulting by proven experts

- Reduced testing costs thanks to safe, reliable fault detection

- High number of mating cycles thanks to high-performance materials

- Efficient test technology even in the smallest installation space

- Four-wire measurement technology for highly precise measurements of electrical currents and resistances

- Floating bearing for optimum tolerance compensation

- 100 percent final inspection of TEKON test fixtures before delivery

- Test fixtures for extremely high currents in a small installation space (high “current density”)

- Test fixtures with integrated monitoring of electrical currents, temperatures and accelerations

- On request, special surfaces or coatings for different cleanliness classes (for example medical technology and food industry)

Customer Service

Contact us with your questions about training, maintenance, repair, take-back service or online support.

We are here for you!

Phone +49.7151.36884 0 /

Mobile +49.170.8118657